MCI’s capabilities begin with an in-house team of engineers and designers who are highly experienced in creating control solutions for numerous industries and applications. Our capabilities allows us to add value for our customers, as well as aiding us in becoming a global leader in the industry.

Efficiency & Automation

MCI has the second largest panel shop in the United States. The state-of-the-art full 5S facility is fully automated with the best manufacturing equipment available. These advantages offer our clients streamlined efficiency and automation which results in the ability to manufacture products on a large scale with smaller lead times, reduces cost, and delivers higher quality products. MCI gives our customers options that are unable anywhere else in the world and allows us to meet or exceed our client’s exact needs precisely and rapidly.

Engineering & Development

MCI’s dedicated team of 24 electrical and mechanical engineers are experienced in creating first-class control solutions that meet NEC, UL/CUL Listed, and CSA certification standards that meet our customer’s exact requirements for a wide variety of industries and applications. MCI closely works with our customers from concept through manufactured products. Our engineering and design team provides customers with complete solutions for products, services, and support.

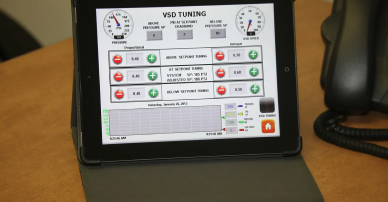

Quality & Support

Our quality managers partner with customers from beginning to completion of each project to keep our focus on customer requirements and standards. And along with our quality solutions that deliver superior performance, we provide customers added value through continuing support. MCI ensures quality through rigorous testing, to make certain every control solution meets every specification. Our customers can feel confident our products are the best available through a manufacturing process that meets or exceeds global standards certification processes.

Enclosure & Structural

MCI offers an extensive selection of Standard, pre-engineered enclosure platforms that can be cost-effectively modified to accommodate requirements of many applications. MCI also offers specialized enclosures that may involve harsh environments, special ergonomic considerations or other unique specifications. MCI structural racks are designed to your specifications with High-Strength structural steel C-Channel and/or I-Beam support to protect your control panels.

Graphics & Branding

MCI’s in-house graphics and printing department offers clients capabilities that truly customizes our products. Options include custom logos, custom labels, wiring labels, laser engraving, vinyl overlays, and many more advantages which add the perfect touch to any control solution. Our team of designers work closely with customers to ensure design needs are met and function as intended.